WhatsApp

WhatsApp

This customer is an activated carbon manufacturer. Considering the environmental protection effect, automation degree, equipment maintenance cycle and other factors, the customer chose the vertical mill. The company’s professional and technical personnel compared to a number of vertical mill manufacturers on the market, finally chose SBM. This equipment configuration plan is made by SBM and the customer’s technical personnel.

Material: Coal, semi-coke, asphalt mixture

Input size: ≤20mm

Output Size: 200mesh D90

Capacity: ≥20t/h

Equipment:

LM190 Vertical Grinding Mill Enclosed quantitative feeder Electric control cabinetThe noise is below 85db. The full seal system works under the state of negative pressure without dust flying. It’s very eco-friendly. And the capacity also reached our requirement. We’re satisfied with SBM’s LM Vertical Grinding Mill.

F5X Vibrating Feeder Having strong vibration intensity; suitable for super-…

What mechanical equipment is needed for artificial sand making Artificial s…

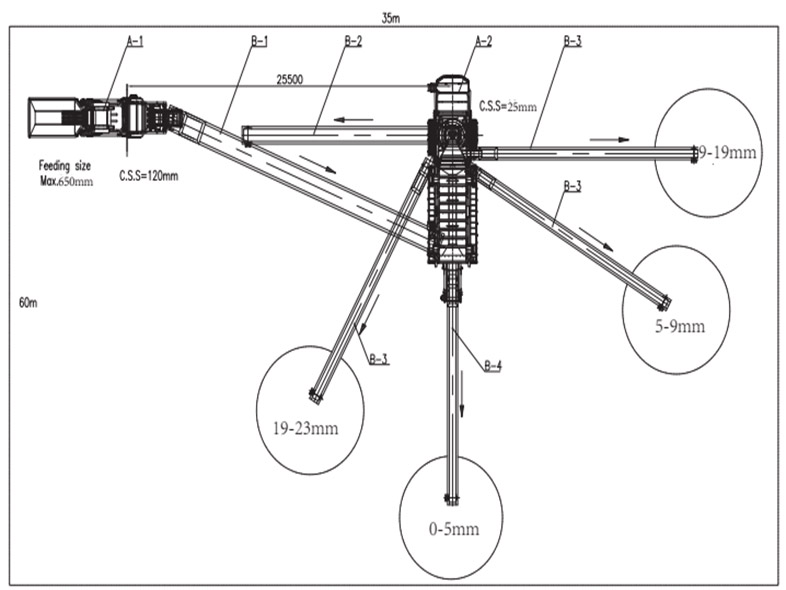

Zambia 200TPH Granite Crushing Line After president election in 2015, the n…

VU Tower-like Sand-Making System Eco-friendly production standards, better …