WhatsApp

WhatsApp

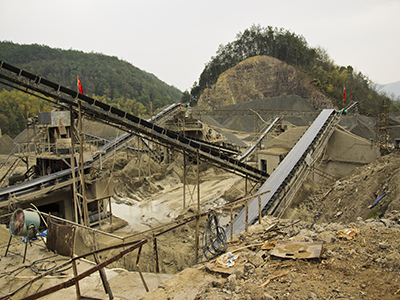

In general, an iron ore crushing production line consists of several machines that work together to break down the raw iron ore into smaller pieces. This typically includes a jaw crusher for primary crushing, a cone crusher for secondary crushing, and a vibrating screen or other sizing mechanism to classify the ore into different sizes. The crushed iron ore is then typically transported to a grinding mill where it is further processed into a fine powder. This powder is then mixed with water and other chemicals to create a slurry that is fed into a blast furnace, where it is heated to a high temperature to produce molten iron.

Iron ore crushing production line typically involves crushing the iron ore to a specific size, and then separating the iron ore into different sizes for further processing. The crushing process usually involves jaw crushers, cone crushers, and other crushing equipment, such as impact crushers and hammer mills. The size of the crushed iron ore is then screened and sorted to obtain different sizes for further processing. The extracted iron ore can be used in a variety of applications, including the production of steel and other alloys, as well as in the production of iron-based chemicals and fertilizers.

An iron ore crushing production line is a series of machines that are used to process iron ore. The production line typically starts with a machine that grinds the iron ore into smaller pieces, followed by machines that crush the ore into even smaller pieces. These machines may include crushers, ball mills, and other grinding equipment. The crushed iron ore is then processed through screens and magnetic separators to remove any impurities, such as sand or rocks. The final product is iron ore in its purest form, which can be used in a variety of applications, including steel production.

Iron ore crushing production lines vary depending on the type of ore being mined, the equipment being used, and the stage of the mining process. In general, however, the crushing process begins by feeding the iron ore to a crusher, where it is crushed into smaller pieces. The crushed ore is then transported to a processing plant, where it is crushed and screened to produce the final product. This process may involve a series of crushing and screening stages to produce the desired size and quality of iron ore.